Tuning Basics

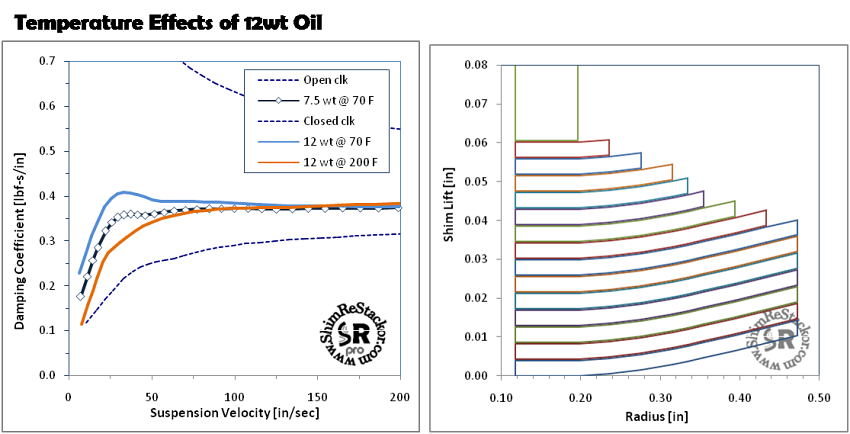

Oil Viscosity Effects on the Damping

At low suspension velocities flows through the suspension circuits are laminar and influenced by oil viscosities. Increasing the oil viscosity can drive a linear damping profile into a digressive shape, reducing the oil viscosity has the opposite effect.

Oil viscosity effects built into ReStackor pro give you the capability to tune damping profiles using oil viscosities.

Effect of oil viscosity on damping

At low suspension velocities the shim stack is barely cracked opened creating a thin annular gap. The thin annular gap creates a flow geometry with a high surface area per unit flow area. The high surface area amplifies oil viscosity effects and increases the pressure loss and damping force of the shock absorber. This effect creates the differences in damping forces seen in the above figure.

At higher suspension velocities the increased shim stack flow area reduces the ratio of surface area per unit flow area and the effect of oil viscosity. This effect results in the digressive damping curve for the 12wt oil case above suspension velocities of 20 in/sec. The 2.5wt oil case does not have this digressive behavior since the viscous pressure losses are lower. In this case the damping profile is dominated by the shim stack stiffness.

At high suspension velocities the flow area produced by the shim stack is large enough that the surface area of the valve seat becomes a negligible fraction of the fluid flow area. Here oil viscosity has a negligible effect on the pressure loss since valve seat surface area is a negligible fraction of the total flow area. At high suspension velocities the damping forces produced by 12wt oil are virtually identical to 2.5wt oil case. This effect emphases that you can never correct for rider weight or changes in spring rate by simply changing the oil viscosity in the suspension system.

The specifics of how a suspension will respond to a change in oil viscosity depend on the specifics of the shock absorber flow circuits. The influence of oil viscosity depends on the stiffness of the shim stack, the surface area of the valve seat, the geometry of the valve port, the bleed circuits and the diameter of the shock absorber damper rod and its influence on oil flow rates through the suspension. There is no single parameter. The calculations of ReStackor give you the capability to model each of these parameters and evaluate the integrated effect of these parameters to determine the influence of oil viscosity on suspension damping rates.

![]()

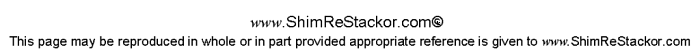

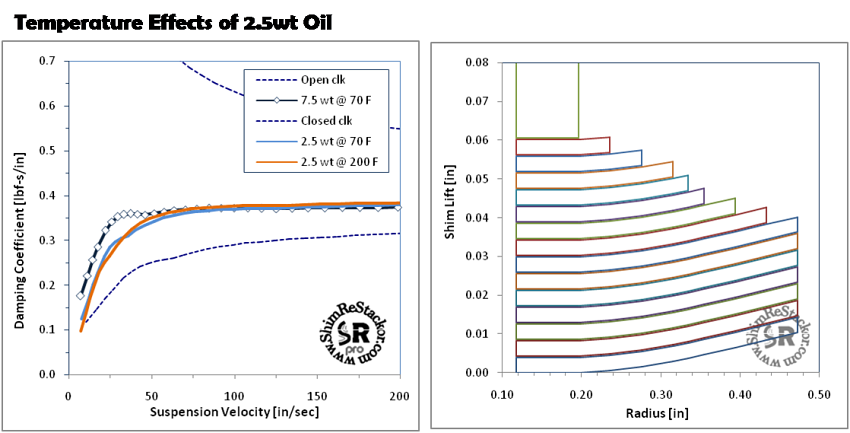

Oil temperature effects on damping

The fluid viscosity relationships built into ReStackor pro include the effect of temperature on oil viscosity. This allows you to evaluate the potential for suspension fade at high oil temperatures. Lightweight oils produce little change in damping with increased temperature since the viscous damping forces generated by the suspension fluid are low in the first place. For the above example increasing the oil temperature from 70 F to 200 F produces little change in the shape of the damping force curve.

Since lightweight oils produce little viscous damping effects the oil is not sensitive to temperature changes.

Thicker oils produce more damping force at low speed due to viscous interactions of the suspension fluid with the flow circuits of the shock absorber. This results in thicker oils being more sensitive to temperature changes. Increasing the oil temperature of SAE 12wt oil from 70 F to 200 F drives the damping profile from a digressive curve to a progressive profile. While the temperature change effects low speed damping there is little difference in the high speed damping since the high speed damping rates are primarily driven by fluid momentum forces not viscous forces.

Thicker oils influance low speed damping rates and are sensitive to changes in oil temperature.