ReStackor Anchored To Real World Dyno Data

Dyno data for motorcycle suspension at www.supercross-online.de has measured effects of stack clamp diameter, crossover shims, stack taper and fluid viscosity on damping performance of motorcycle suspensions. Configurations as simple as flow through the clicker bleed circuits to complex mid-valve stack configurations have been tested and used to verify all aspects of ReStackor calculations. Dyno work of supercross-online has relentlessly pursued the fundamentals of suspension tuning and demonstrated those principals through dyno tests of actual suspension hardware.

![]()

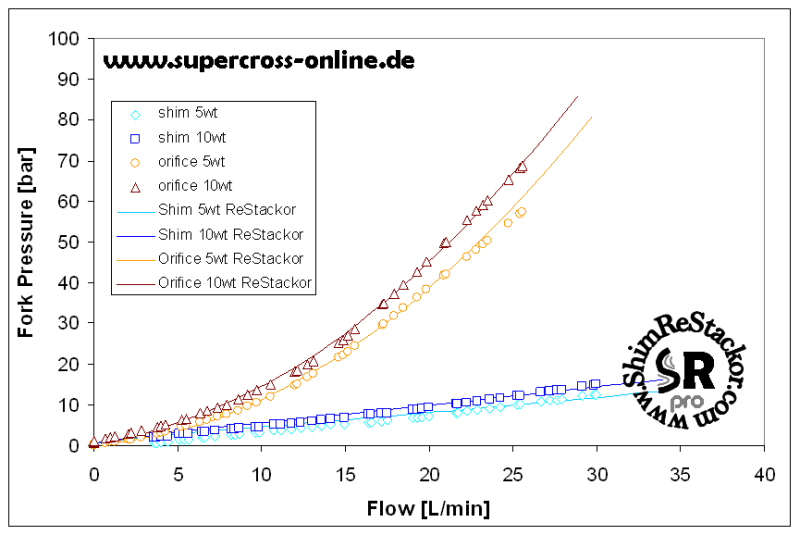

Viscosity Effects Accurately Modeled By ReStackor

Supercross-online.de has measured the flow resistance and effects of fluid viscosity changes on simple orifice flows and the flow rates through suspension valves. ReStackor matches the dyno data over the entire range tested.

Viscosity relationships built into ReStackor pro accurately match dyno data measuring effects of fluid viscosity changes on suspension performance. Oil flow rates of 30 L/min are equivalent to a base valve velocity of 150 in/sec.

ReStackor pro accurately computes the effect of fluid viscosity changes on the flow resistance through suspension components. This allows you to test ride your bike using different oil viscosities and use that data to quantify specific shim stack configuration changes to reproduce those effects. You can tune the low speed stack to the performance of 2.5wt oil and the high speed stack to the performance of 10wt oil or visa-versa.

ReStackor uses the real world commercial suspension fluid viscosity data complied by Peter Verdone to establish the relationship of SAE wt to fluid viscosity. The Andrade [1] equation is used in ReStackor to determine temperature effects on oil viscosity; match published viscosity data at cSt@40c and cSt@100c; and accurately extended that data to subzero temperatures or the high fluid temperatures causing suspension fade under hard use.

[1] Reid, R.C., Prausnitz, J.M. and Sherwood, T.K.,”The Properties of Gases and Liquids”, McGraw-Hill 1977.

![]()

Dyno Data

Working new dyno data over a broader range of forks and shock applications.

Check back for updates........................