Mid-Valve Cavitation

Motorcycle suspension tuning of an MX mid-valve setup is easy using the spreadsheet interface of ReStackor. The ReStackor-midvalve.xls spreadsheet computes the damping force of the base valve, mid-valve and the combined system. Cavitation limits of bladder or ICS systems are determined allowing you to tune the shim stack, valve ports, and pressurization system to control the damping force of the integrated system.

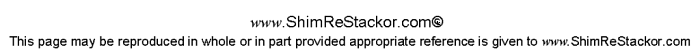

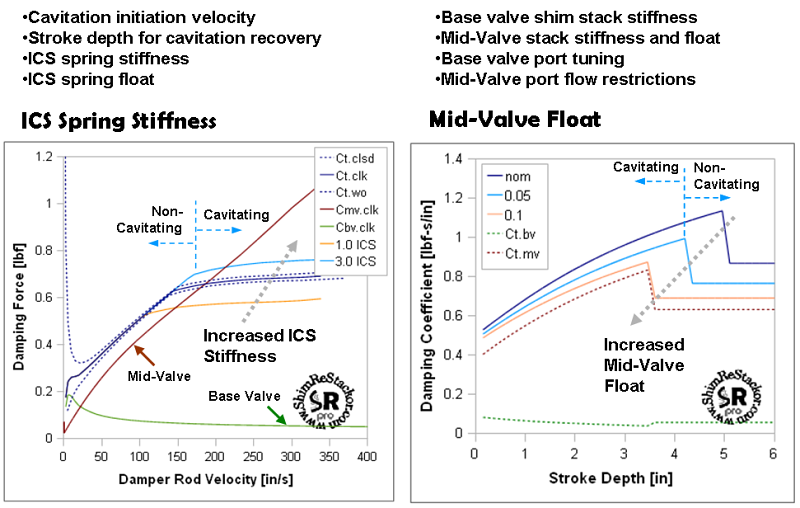

The combined damping force of the base and mid-valve produces three distinct regions. ReStackor pro gives you the capability to understand the influence of each valve in each region, tune damping forces in that region and control the suspension velocities where the system transitions from one region to the next.

ReStackor pro gives you the capability to tune damping forces produced in each region of the damping force curve, the transition velocity in each region and the cavitation limits of the suspension.

![]()

The capability of ReStackor pro to model the physical processes occurring within the guts of a shock gives you the capability to experiment, test and understand the influence of each component on the overall damping performance of the shock. Combining analysis with a fundamental understanding of the physical flow processes occurring within a shock produces a powerful tuning tool.

Region I: Low Speed

Low speed damping is controlled by the stiffness of the base valve shim stack and clicker settings. Tuning float on the mid-valve controls the suspension velocity where damping forces transition to mid-speed.

Region II: Mid Speed

Mid-speed damping is controlled by the combined force of the base and mid-valve. MX suspension setups use stiff mid-valve shim stacks to control bottoming on large hits. Enduro setups use softer mid-valve shim stacks and larger values of stack float to allow the suspension to absorb bumps rather then jump over them.

Region III: High Speed Cavitation

Stiff mid-valve shim stacks and low values of stack float will cavitate the rebound chamber during the compression stroke. When cavitated, compression damping increases and the following rebound stroke produces zero damping while the cavitation bubble collapses.

ReStackor models the physical flow processes defining cavitation limits and the performance of the suspension when driven beyond the cavitation limit. The physics of flow cavitation are all handled internally within the code giving you the capability to simply enter a shim stack, click a button, and determine the suspension performance evaluating all of the following effects.

ReStackor pro gives you the capability to determine the suspension velocity cavitation limit, tune the stiffness of mid-valve shim stacks , shock absorber bladder pressures and the stiffness of ICS springs to control cavitation. The capability of ReStackor to model all of the above components gives you the ability to understand the influence of that component on the performance of your suspension and tune that component to control damping force and the operation limits of your suspension across the entire range of suspension speeds.

![]()

Cavitation

At

high suspension

speeds

the

pressure

drop

across

stiff mid-valve compression stacks can drive

pressures in the rebound chamber to near vacuum conditions. When

the

pressure

falls to the vapor pressure of the hydraulic

fluid a vapor vacuum bubble forms. This is known as cavitation. The occurrence

of violent

cavitation

in

the

rebound chamber during the

compression

stroke, and the capability of a shock to instantly recover from

that cavitation, has been eloquently videoed by Roehrig.

When

the

suspension

is

driven beyond the cavitation limit

the mid-valve cannot deliver the

volume

of

fluid necessary to keep the

rebound chamber filled with fluid.  Excess

fluid that can not pass through the mid-valve is pushed out through the

base valve. This cavitation driven flow surge

into

the

fluid

reservoir

increases

the

back

pressure

produced

by

the

bladder or ICS system

and partially heals the cavitating mid-valve flow (more).

Excess

fluid that can not pass through the mid-valve is pushed out through the

base valve. This cavitation driven flow surge

into

the

fluid

reservoir

increases

the

back

pressure

produced

by

the

bladder or ICS system

and partially heals the cavitating mid-valve flow (more).

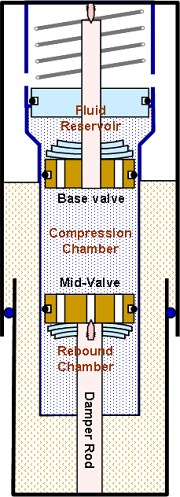

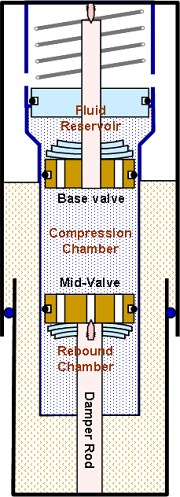

Fluid Volume Balance

The fluid volume balance built into ReStackor pro tracks the volume of fluid in each chamber of the shock, computes the fluid circuit flow velocities necessary to maintain that volume balance and the reservoir pressures produced by bladder or ICS systems under both non-cavitating and cavitating conditions. Thorough formulation of the volume balance gives ReStackor the capability to determine the volume of the cavitation bubble and the magnitude of the cavitation driven flow surge. Quantifying the flow surge allows ReStackor pro to determine the stroke limits of ICS pistons and the potential for damage of plastic ICS pistons when cavitation drives the piston beyond the designed stroke limits (more).

Force Accounting

For both cavitating and non-cavitating conditions the force on the shock damper rod is simply equal to the difference in pressure on the front and back face of the mid-valve piston. Pressure in the compression chamber is controlled by the base valve and the back pressure of the fluid reservoir. Pressure in the rebound chamber is controlled by the pressure drop across the mid-valve. The difference in pressure produces the damping force. The fundamental capability of ReStackor to compute shim stack stiffness and pressure drops through the shocks fluid circuits allow the damping force to be computed through a straight forward pressure based force balance under both cavitating and non-cavitating conditions.

Suspension Tuning

The graphical user interface of ReStackor produces simple easily understood plots. This gives you the capability to easily run "what if" scenarios to develop an understanding of the influence of each component on damping performance. Integration of the base and mid-valve into a single calculation gives you the capability to simultaneously modify shim stacks on both valves, understand the interaction of those changes, the velocity range and bump height where each valve controls damping, and reshape the damping force curve to obtain the damping profile you want while maintaining bottoming resistance.

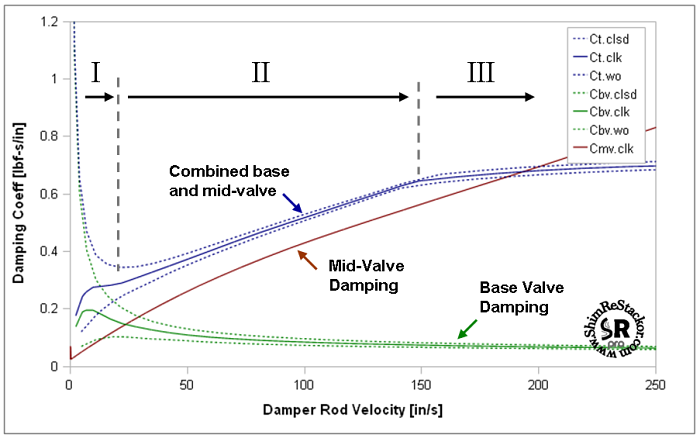

![]()

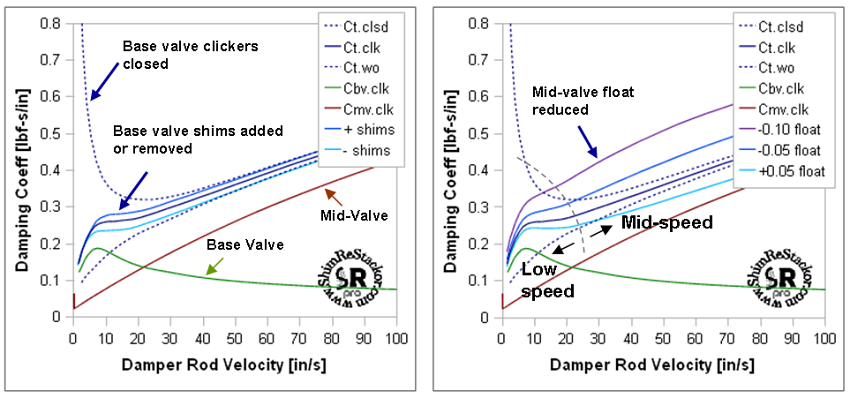

Low Speed Compression Damping

Low speed damping can be tuned by changing the stiffness of the base valve shim stack or the mid-valve stack float. Changing the base valve stiffness effects both low speed and mid-speed damping. Modifying the mid-valve float influences damping in the low speed range and the velocity where the suspension transitions to mid-speed. ReStackor pro gives you the capability to tune low speed damping using either approach. Computing damping force of the combined base valve and mid-valve is a simple matter of entering the stacks and clicking a button to produce the plots below. Referencing the stacks to the clicker ranges of your current setup (Ct.clsd and Ct.wo) makes damping performance evaluations a simple and intuitive task.

ReStackor pro gives you the capability to evaluate changes to the base valve shim stack and mid-valve stack float and relate those changes to the clicker settings of your existing setup.

Float values on the mid-valve stack control transition from low speed to mid-speed damping. Lower values transition earlier. In the example above reducing the mid-valve float by 0.1mm almost completely eliminates the linear portion of the low speed damping curve.

![]()

Mid-Speed Compression Damping

Mid-speed damping is controlled by the combined damping force of the base and mid-valve. Decreasing the mid-valve stiffness moves the damping curve toward a flat linear profile. Changing the mid-valve shim stack stiffness has little effect on low speed damping. The combination of float and stack stiffness gives you the capability to independently control mid-speed damping.

Increasing the stiffness of the base valve shim stack effects both low speed and mid-speed damping. Crossover shims can be added to the base valve stack to modify that behavior. Parametric calculations give you the capability to understand the effect of each valve, tune the damping force produced by that valve, control suspension velocities where each valve effects performance and understand effects of shim stack modifications before the stacks are installed in your bike. Evaluating effects of potential modifications over the entire range of suspension velocities helps to insure that the modifications you make do not produce unexpected side effect at other suspension velocities.

Plotting the combined damping force of the base and mid-valve allows the effect of each modification to be determined before the modified stacks are installed on your bike.

![]()

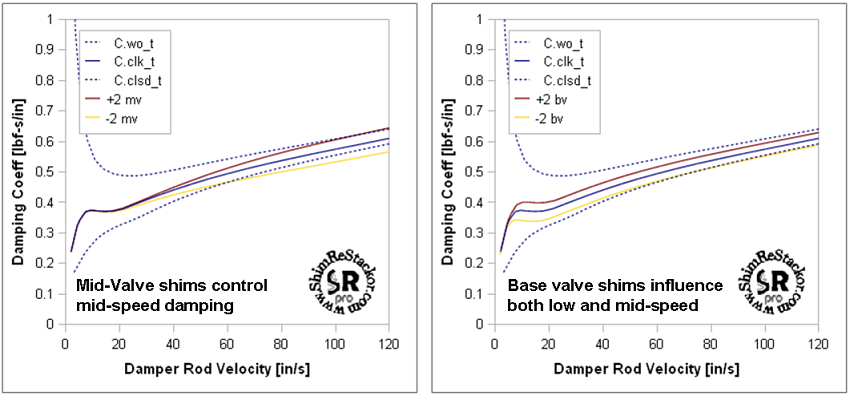

High Speed Damping

Stiff mid-valve shim stacks can cause the rebound chamber to cavitate at high suspension velocities. When cavitation occurs damping rates in both the compression and rebound stroke are effected. ReStackor pro has the capability to evaluate cavitation limits, the suspension velocities where cavitation initiates and the damping forces produced when the suspension is driven beyond the cavitation limit.

Shock Bladders

Bladders pressurize the fluid reservoir of a shock and backpressure the fluid circuits to maintain pressures above cavitation limits. Low bladder pressures, stiff mid-valve stacks or soft base valve stacks can drive the shock absorber into cavitation (more) .

Increasing shock reservoir bladder pressure raises the cavitation limit to a higher suspension velocity.

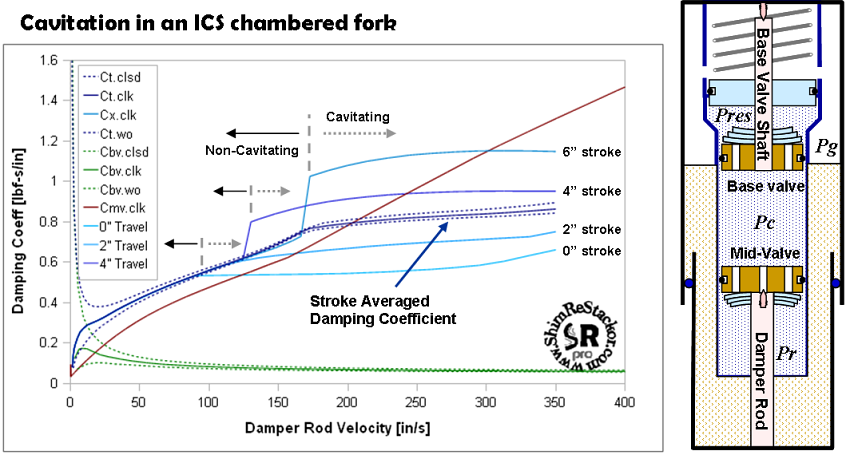

ICS Piston

Pressures produced by an ICS system in the fluid reservoir of a shock are a function of the ICS spring stiffness and the suspension position. As the suspension is driven deeper into the stroke, fluid entering the ICS chamber compresses the piston spring and builds pressure in the fluid reservoir. Cavitation in an ICS system is a function of suspension position, velocity, ICS spring stiffness and the flow resistance of the base and mid-valve shim stack (more) .

Stiffer ICS springs extend cavitation limit to a higher suspension velocity.

Mid-Stroke Harshness

In a motorcycle fork it is desirable to have near zero spring force at the top of the stroke. This allows the suspension to float over small bumps when the bike is under hard acceleration or on a hill climb. To satisfy that criteria, ICS systems produce near zero pressurization of the fluid reservoir at full extension of the suspension. This results in a system that is easily cavitated at the top of the stroke and then recovers from cavitation as the ICS system builds pressure deeper in the stroke. Allowing the suspension to flip into and out of cavitation over the coarse of the stroke results in inconsistent damping and a number of suspension ills often summed up as mid-stroke harshness.

With stroke depth controlling ICS pressurization and suspension velocity controlling cavitation the tuning of an ICS system is not easy. Suppressing cavitation requires tuning the base valve stack stiffness, mid-valve stiffness, stack float, and ICS system to all simultaneously operate within the limits of cavitation. The physics based models of ReStackor give you the capability to parametrically test and understand the influence of each component in the system, identify the components that are controlling the suspension behavior and tune those components to control the system. Simultaneous control of these multiple parameters when trying to tune the system by the seat-of-the-pants is very difficult. ReStackor gives you the capability to understand the interaction of these multiple components and tune your suspension far beyond the limits previously possible (more) .

Cavitation limits in an ICS chambered fork are a function of suspension velocity and stroke depth.

![]()

Accuracy

Cavitation limits are defined by small differences in large numbers. If the base or mid-valve pressure drop is off by 10 psi one way or the other the impact on overall damping force is small. But, if the base valve pressure drop is 10 psi high and the mid-valve is 10 psi low the 20 psi swing in pressure has a large impact on cavitation. Due to this sensitivity cavitation limits are difficult to compute without specific calibration of the calculations for each specific suspension setup. Test rides are needed to quantify performance.

The central focus of ReStackor is tuning suspensions based on the results of test rides. In-situ tuning gives you the capability to test your suspension on the actual terrain and the actual speed that you ride and relate suspension performance and clicker settings to the specific shim stack modifications needed to achieve specific damping rates.

Here, under actual ride conditions, it makes little difference whether your suspension cavitates at the suspension velocities of a 4 inch bump or a 5 inch bump. The fact is it cavitates and cavitation produces a range of suspension ills easily identified by the calculations of ReStackor. Understanding the effects of cavitation on suspension performance and the capability to identify the specific suspension components causing cavitation gives you the analytical tools needed to tune those components to control cavitation. The capability to do that depends on your ability to implement the art of suspension tuning and interpret the vague details of suspension feel to the specifics of computed damping force, component performance and cavitation limits.

Suspension tuning is and remains an art. ReStackor simply supplies the tools needed to interpret and implement that art.

![]()

Suspension Cavitation Limits

The fundamental capability of ReStackor to compute pressure drops through suspension circuits provides the information needed to understand and control cavitation limits. Easily interpreted plots quantify the performance of each component in the shock. Effects of modifications to those components on the overall system operation are easily interpreted. Plots of the pressure in each chamber of the shock allow the onset of cavitation to be easily identified as well as the modifications needed to avoid cavitation. The ReStackor fluid volume balance quantifies the magnitude of cavitation and the effect of cavitation events on overall system performance.

ReStackor gives you the

capability to understand the details of shock operation and the interaction of components within the

shock on overall performance. That understanding of the system operation

and component interaction gives you the capability to easily tune the

damper:

-

Stiff mid-valve shim stacks can drive the rebound chamber into cavitation during the compression stroke. ReStackor gives you the capability to tune the mid-valve stack float, stiffness and fluid reservoir pressurization system to control the initiation and recovery from cavitation.

-

Base valve stack stiffness can be tuned to suppress mid-valve cavitation through control of the shock compression chamber pressure.

-

Bladder pressure can be tuned to control the suspension velocity where cavitation initiates.

-

Bladder volumes can be tuned to accelerate cavitation recovery deeper in the stroke.

-

-

ICS spring float can be tuned to accelerate cavitation recovery.

-

ICS spring stiffness can be tuned to control the suspension stroke depth required for cavitation recovery.

-

The ICS system can be tuned to match a mid-valve shim stack setup or the mid-valve can be tuned to match the ICS system.

-

-

Cavitation of the rebound chamber during the compression stroke results in zero damping during the following rebound stroke while the cavitation bubble collapses. ReStackor gives you the capability to quantify the size of the cavitation bubble produced and the capability to tune the suspension components to control the magnitude of rebound damping loss.

-

The cavitation flow surge into the fluid reservoir can over stroke and damage ICS pistons. ReStackor quantifies the magnitude of the cavitation driven flow surge and gives you the capability to tune the system for control of ICS piston stroke depths.

Solid fluid dynamic models implemented within the framework of conservation of mass and momentum in ReStackor provides an engineering analysis tool capable of quantifying the effect of each component in the shock on overall system performance and suspension operation over the entire range of suspension speeds. This gives you the capability to test and experiment with the tuning of each component and understand the influence of that component on overall system performance. Developing an understanding of component performance allows the overall system to be tuned and the specific components controlling suspension operation identified as a function of suspension velocity and stroke depth. Understanding the influence of each component gives you the capability to tune those components and exploit the features of each component to optimize the system performance and control damping forces over the entire range of suspension speeds.

ReStackor gives you the capability to understand and tune your suspension far beyond the limits previously possible.