Crossover gaps

The stack force balance computed by ReStackor is a useful diagnostic tool when working with crossover stack configurations. The ReStackor stack deflection plot allows you to determine the point ware crossover gaps closes and view interactions with other shims in the stack. These simple capability significantly improves your ability to tune a shim stack.

The crossover closure point is be controlled by the thickness of the crossover shim, the crossover shim diameter and the location of the crossover shim in the stack. The stiffness of the initial rate, up to the point where the crossover closes, can be controlled by the number of face shims, the crossover shim diameter and the diameter of the stack clamp shim. The ReStackor force balance is capable of computing the all of these parameters allowing you to experiment with different stack configurations and tune the crossover closure point to control the stack stiffness before and after the crossover closes. This will save you a huge amount of time when tuning a crossover by insuring the changes you make not only have the desired effect both before and after the crossover closes.

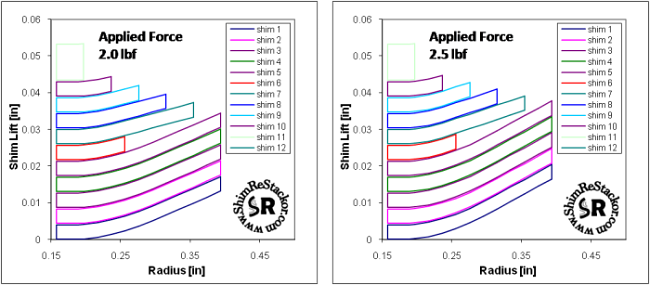

Stiff face shims transfer forces through root of stack and deflect backing shims before crossover closes.

At low lift the crossover is open and the outside edge of the face shims are not supported making the initial stiffness of the stack low. For this stack the face shims are much stiffer than the backing shims. The stiff face shims transfer forces through the root of the stack and produce deflection of the backing shims before the crossover gap is closed. At an applied force of 2.5 lbf the crossover gap closes.

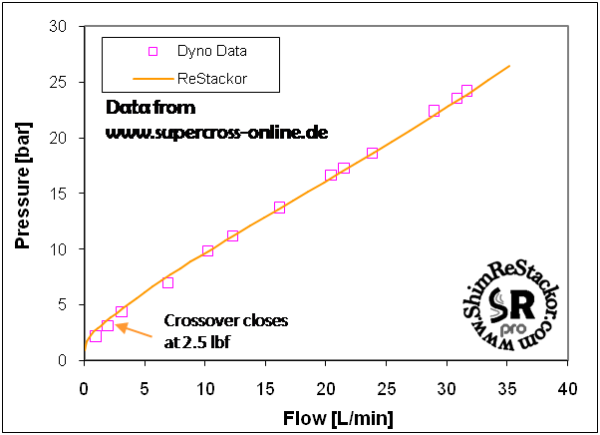

Stack Stiffness Compared to Dyno Data

The stack stiffness and flow resistance computed by ReStackor pro for this configuration compares well with the dyno test data of supercross-online.de. The close comparison indicates that the stack stiffness and flow area computed by ReStackor pro are correct for this stack configuration.

ReStackor pro accurately matches dyno test data for crossover stack configuration.

Crossover Effect on Stack Stiffness

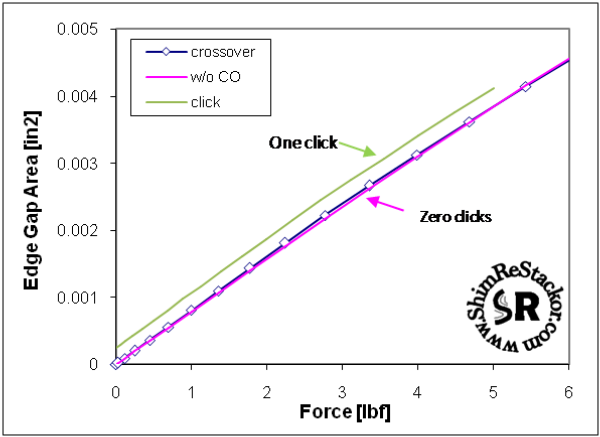

The point where the crossover gap closes can be seen in the stack stiffness plots computed by Shim ReStackor. For the stack configuration tested the effect of the crossover is very subtle producing almost no change in the stiffness of the stack.

Crossover shim produces small effect due to weak backing shim structure.

The effect of the crossover shim on stack stiffness was evaluated by running stack calculations both with and without the crossover. With the crossover removed the flow area between the valve face and shim stack is shown by the pink curve in the plot above. The tested stack configuration with the crossover installed is shown by the blue curve. Adding the crossover produces a very small increase in flow area. The maximum effect of the crossover occurs just before the crossover closes at approximately 2.5 lbf.

Opening the bleed clickers by one click, the green curve, produces a much larger change in flow area then the addition of a crossover shim. The crossover increases the flow area of the stack by approximately 1/3 of a click.

If you were developing this stack through the classic butt dyno testing process you would be very disappointed with the results of this stack. The above modification does very little to alter the stiffness of the stack. In the butt dyno development program where would you go from here? Add a thicker crossover shim or alter the taper of the backing shims?

This is where an analysis tool like ReStackor can save you a huge amount of time. With ReStackor you would know the stack configuration tested above would produce very little change in stiffness so you wouldn't waste your time installing and testing the stack in the first place. Beyond that, the stack deflection plots of ReStackor show you why the crossover has little effect. The face shims for this stack are much stiffer than the backing shims. For the crossover shim to produce the desired effect a stiffer backing structure is needed.

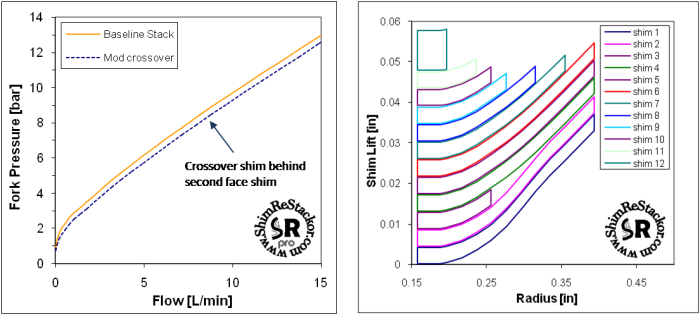

If the crossover shim is moved closer to the face shim the effectiveness of the crossover is increased. Positioning the crossover behind the second shim decreases the initial stiffness of the stack by approximately one click.

Moving crossover shim forward in the stack increases the effectiveness of the crossover.

Creating stack configurations is truly an art. For something as simple as inserting a crossover shim there are numerous decisions to make. Where should the crossover be inserted? What diameter? What thickness? After making these decisions you are left with the age old question “Is this stack stiffer or not?”. ReStackor is designed to answer those questions and provide the capability to make smart decisions in configuration of the stack. ReStackor will help to insure that the changes you make to a stack are not only in the right direction but also the right magnitude. That is a huge streaming of the entire tuning process.