Calc k.sprng

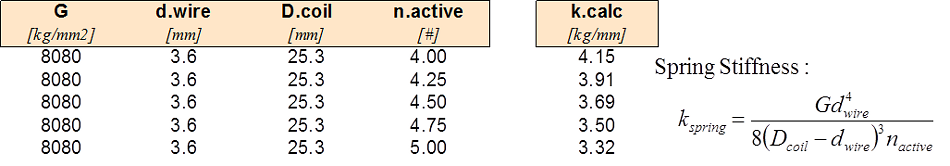

Spring Stiffness

Estimating the spring constant for a coil spring is straight forward. All you need is the wire diameter, spring diameter and number of active coils. Given those parameters the spring stiffness is given by:

The art of computing spring stiffness is figuring out how many of the spring coils are active (n.active) in the spring.

Active Coils

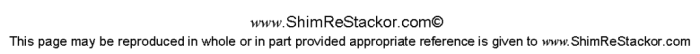

At each end of a spring the last coil is typically collapsed and ground flat making the end of the coil flat and square. The first active coil begins at the point where the wire pitch departs from the collapsed coil end. This is the zero point for counting active coils. Each full revolution of the wire counts as one active coil.

The example below demonstrates a coil spring with a dead wrap at each end. The number of active coils increases from 4 to 5.

The example below shows how the spring stiffness decreases as the number of active coils increase.

If the number of active coils drops from 5 to 4 the spring rate increases by 25%. That process is used to make fork springs stiffer by simply cutting off a couple of coils.

For high speed compression adjuster springs, or mid-valve check springs, the spring stiffness of stock or after market springs are typically not known. The above process provides a method to estimate spring stiffness, the key is knowing how to figure out the number of active coils in the spring.